A Unique Technology

Thanks to our design office, we develop recycled elastomer thermoplastics that maintain their mechanical properties. Our technicians guarantee high-quality elastomer materials.

1- Rubber Recycling

Our suppliers collect end-of-life tyres and shoes.

2- Shredding

Our suppliers grind and transform tyres into vulcanised rubber granulate powder.

3- Elastever's Technology

Our formula and process create the first elastomer material to contain over 70% recycled tyres.

4- Recycled and Recyclable Materials

Our new elastomer product has mechanical properties comparable to those of virgin petroleum-based materials.

It is 100% recyclable using mechanical recycling techniques.

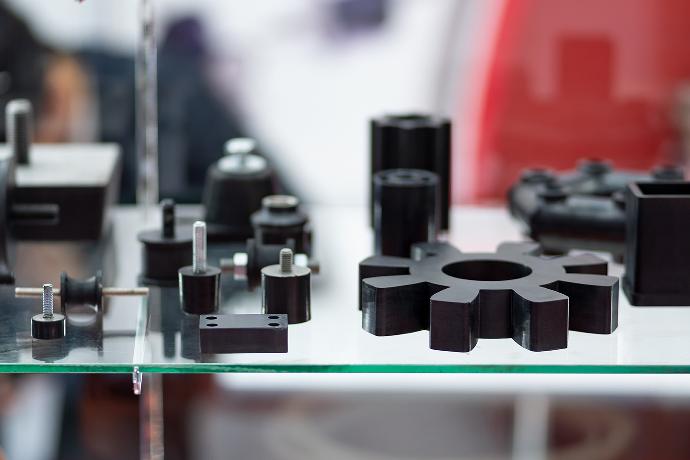

5- Extrusion, Injection, Compression Moulding

Our materials, in pellets, are intended for plastics manufacturers who use them in injection, extrusion or compression moulding.

6- More Than Just a Material !

Elastever products form a range that varies in hardness and fluidity according to customer requirements.

Recycled Raw Materials

Elastever develops thermoplastic elastomer formulations from recycled raw materials, in particular recycled thermoset elastomer powders. These recycled raw materials come mainly from the end-of-life tyre and footwear industries.

We produce these materials in pellet form, for use in injection, extrusion or compression moulding.

A Unique Formula

Our products are characterised by :

- A very high recycled content (>70%)

- 100% recyclable

- A low price, on par with the cheapest elastomers

Made In France

The materials are manufactured in our own facility in France.

The hardness of the materials varies from 50 ShA to 90 ShA.

Plastics processors can use their existing machines to process our materials.

In addition to the standard range, Elastever can develop customized formulations to meet your needs.